LED Lamp Cure Machine

JHCI-3014EC (OLED/AMOLED PANNEL)

As a complex UV curing machine for upper and side parts, this equipment is a UV system that combines upper and side parts UV curing processes conducted for UV bonding of window glass and touch panel in the cellular phone touch screen (OLED/AMOLED) manufacturing process into single process.

Feature

Feature– Complex UV curing machine is the curing machine that incorporates UV side and upper parts curing system.

– Both UV metal halide lamp and UV mercury lamp can be used.

– Both UV metal halide lamp and UV mercury lamp can be used.

SPECIFICATION

SPECIFICATIONGENERAL SPECIFICATION

| ITEM | DESCRIPTION |

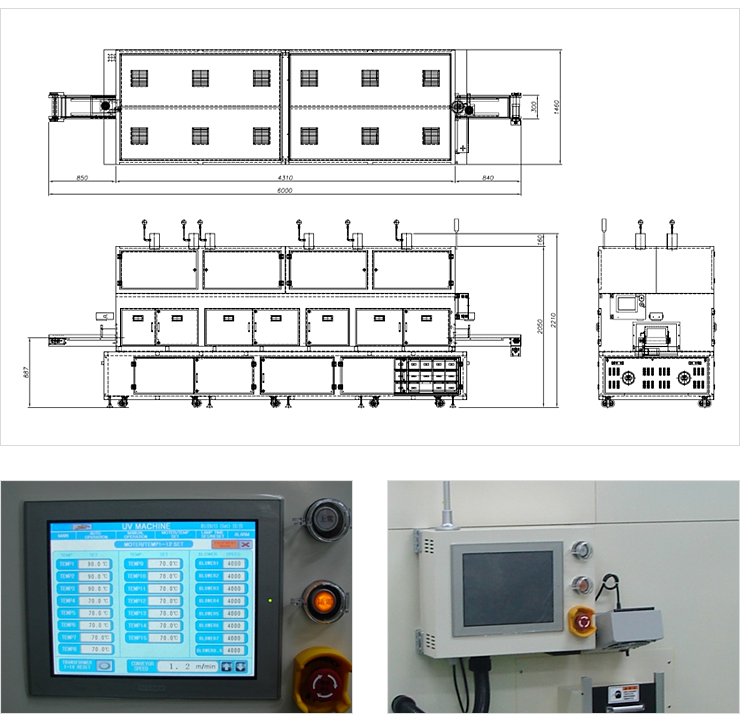

| SYSTEM DIMENSION | 6000 mm (L) x 1350 mm (W) x 2050 mm (H) |

| CURING WIDTH | SIDE 300mm FRONT 200mm |

| INPUT VOLTAGE | 220V , 3P, 60 Hz 225A |

| LAMP TYPE | METAL UV LAMP 3~5 KW – 8~16EA |

| LAMP ARC LENGTH | SIDE 375 mm FRONT 250mm |

| LAMP TOTAL CONSUMTION | 3 ~5KW / LAMP |

| WAVELENGTH | 200 ~ 420 nm(Peak : 365nm) |

| IGNITION TIME | 3 MINUTE |

| REFLECTOR TYPE | COLD MIRROR |

| HOT MIRROR (152X152X2.2T) | OPTION |

| MAIN SWITCH (NFB) | MAIN POWER ON/OFF SWITCH |

| LAMP AMPERE METER | DISPLAY LAMP’S CURRENT |

| LAMP TIME CHECK METER | DISPLAY LAMP’S USED TIME |

| LAMP ALRAM | ALRAM LAMP CHANGE |

| PLC & TOUCH SCREEN | USE |

General Details

General DetailsAs a complex UV curing machine for upper and side parts, this equipment is a UV system that combines upper and side parts UV curing processes conducted for UV bonding of window glass and touch panel in the cellular phone touch screen (OLED/AMOLED) manufacturing process into single process. In case of existing equipment, upper and side parts UV curing systems are split or UV automation of the afore-mentioned process could be accomplished through high-value in-line equipment only.

Owing to the burdens in facility investment cost, the side part UV curing process after upper part UV curing process has been carried out manually. Therefore, the necessity of enhancing competitiveness emerged owing to management cost and labor cost burdens and inefficiency of productivity.

JHCI-3014EC can obtain the effect of reduction of management cost, reduction of the numbers of workers, and improvement of production process by acquiring the effect of automation of production process through improving irrationality of existing process with minimum investment cost.

As OLED/ AMOLED PANNEL UV curing machine, this equipment secured real-time monitoring by adopting RMS communication. Through the composition of an exclusive program, it built universal UV automated system that is easy to cope with a variety of product through selecting the program only. In addition, it allows coping with a variety of sizes (3-8 inches) as well as small-size types, which enables upgrading of UV equipment through application of UV sensor system, etc.

Owing to the burdens in facility investment cost, the side part UV curing process after upper part UV curing process has been carried out manually. Therefore, the necessity of enhancing competitiveness emerged owing to management cost and labor cost burdens and inefficiency of productivity.

JHCI-3014EC can obtain the effect of reduction of management cost, reduction of the numbers of workers, and improvement of production process by acquiring the effect of automation of production process through improving irrationality of existing process with minimum investment cost.

As OLED/ AMOLED PANNEL UV curing machine, this equipment secured real-time monitoring by adopting RMS communication. Through the composition of an exclusive program, it built universal UV automated system that is easy to cope with a variety of product through selecting the program only. In addition, it allows coping with a variety of sizes (3-8 inches) as well as small-size types, which enables upgrading of UV equipment through application of UV sensor system, etc.

Feature & Advantage

Feature & Advantage– Complex UV curing machine is the curing machine that incorporates UV side and upper parts curing system.

– Both UV metal halide lamp and UV mercury lamp can be used.

– Ballast is in an electronic type so that the output of lamp can be freely controlled.

– A sufficient amount of irradiation can be obtained through the illuminance in compliance with the product characteristic and free control of the speed of conveyor belt.

– It is designed to minimize temperature damage applied to the product through cold mirror/hot mirror and exhaust air flow balance.

– The machine’s lamp cooling is carried out in an air-cooling type – having a simple design structure and easy in maintenance. It maintains a stable UV lamp output through the adjustment of cooling quantity.

– With an ionizer installed on the inlet/outlet edges, it improved the quality of product. (option)

– With a simple control through touching function, it provides the worker with convenience.

– Both UV metal halide lamp and UV mercury lamp can be used.

– Ballast is in an electronic type so that the output of lamp can be freely controlled.

– A sufficient amount of irradiation can be obtained through the illuminance in compliance with the product characteristic and free control of the speed of conveyor belt.

– It is designed to minimize temperature damage applied to the product through cold mirror/hot mirror and exhaust air flow balance.

– The machine’s lamp cooling is carried out in an air-cooling type – having a simple design structure and easy in maintenance. It maintains a stable UV lamp output through the adjustment of cooling quantity.

– With an ionizer installed on the inlet/outlet edges, it improved the quality of product. (option)

– With a simple control through touching function, it provides the worker with convenience.

Detail

Detail

UV상부 4등 조사거리 80mm , UV측면경화 10등 조사거리 50mm 조절가능, 컨베어 속도 0.5~3.6m/min 조절가능