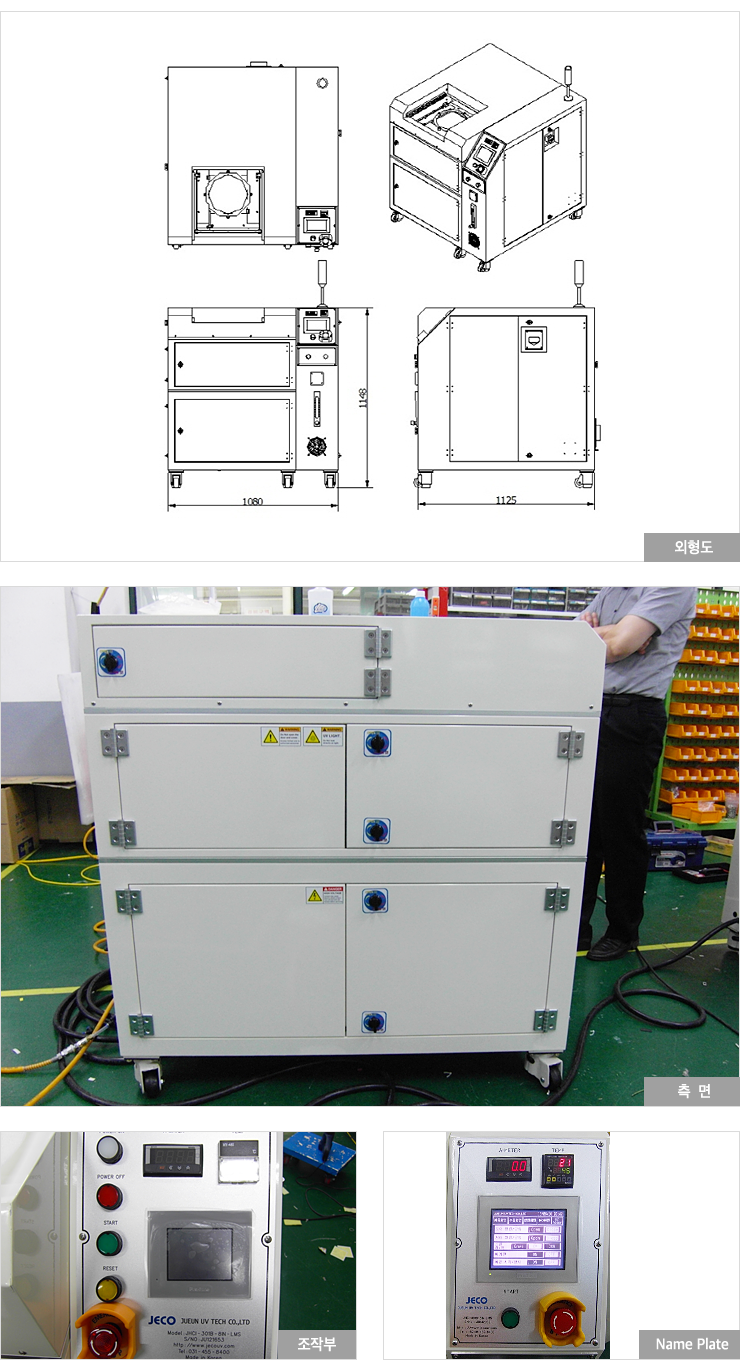

LED Lamp Cure Machine

JHCI-301TB-8IN (UV TAPE REMOVER)

Feature

Feature– Mounted shutter on the top allows to work without being exposed to UV light

SPECIFICATION

SPECIFICATION| ITEM | DESCRIPTION | ||

| SYSTEM DIMENSION | Cure Machine : 1080(W) *1125(D)* 1150(H) | ||

| CURING WIDTH | 8” | ||

| INPUT VOLTAGE | ORDER MADE | ||

| LAMP TYPE | Me or Hg UV LAMP – 1EA | ||

| LAMP ARC LENGTH | 375 mm | ||

| TOTAL CONSUMTION | 3 KW / LAMP | ||

| WAVELENGTH | 320 ~ 420 nm(Peak : 365nm) | ||

| IGNITION TIME | 3 MINUTE | ||

| REFLECTOR TYPE | COLD MIRROR | ||

| HOT MIRROR (152X152X2T) | (OPTION) | ||

| PLC CONTROL | MITSUBISHI : FX3U-48MR | ||

| PLC <-> TOUCH 통신 | MITSUBISHI : FX3U-232BD | ||

| PLC D/A CONTROL | MITSUBISHI : FX3U-4DA-ADP | ||

| TOUCH PANEL | AGP3301-L1-D24 | ||

| INVERTER CONTROL | LS산전 : SV004Ig5-2u | ||

| TOWER LAMP | ST45L-3-220-SZ | ||

| BUZZER | KSP-41S | ||

| UV SHUTTER (UV ZONE) | *AIR SILINDER 250mm *V GUID SYSTEM |

||

| TOP SHUTTER | *AIR SILINDER 450mm *LM RAIL SYSTEM |

||

| COLOR | STANDARD (IVORY) OR CUSTOM COLOR | ||

| ITEM | OPTION | ||

| UV SENSOR | UV 200 | ||

| SIGNAL | *CURE START/STOP *LAMP ON/OFF *RESET |

||

| HOT MIRROR | QUARTZ COATING | ||

General Details

General DetailsUV Tape Remover is JECO wafer-purpose semi-automatic UV curing machine that can cure 8~12 inches. It is designed in the scan irradiation method where the lamp moves with the product fixed, which enables homogenous irradiation of the product by minimizing the tolerance of illuminance (using a filter) based on a long experience and technical competence. In addition, scan frequency can be pre-set, and therefore it is suitable for meeting the required amount of light depending on UV tapes that vary.

Designed to purge nitrogen on the position of product (RING FRAME), it prevents inflow of oxygen. Therefore, the quality of product improves at the time of UV curing through preventing oxidization of UV surface. In addition, it enables high-speed production (option) and is easy to manage the product through the maintenance of low temperature (high amount of light).

Owing to the lamp height being available (manual, step control), it is easy to cope with change in the amount of light following the drop of lamp life. Easiness in replacement of lamp minimizes the loss of time for replacing lamp. In addition, it enables to adjust the UV lamp power output by steps (Transformer 3-step control)

Feature & Advantage

Feature & Advantage2.Mounted shutter on the top allows to work without being exposed to UV light

3. Shutter is equipped with a safety sensor to ensure a safe operation for the worker.

4. Top shutter operation is run by the Air cylinder.

5. When the top shutter is opened, you can see a space to place the product and nitrogen purge can increase the efficiency of UV hardening.

6. Shutter is mounted between the jig and UV lamp of the product, and while setting the product, you are not exposed to the UV light.

7. Not only the jig to place the wafer product but also the quartz to place general types of products are equipped.

8. Product damages are minimal as the product is not moved and hardening is processed by the movement of the UV lamp.

9. Hardening condition setting is easy for any products as hardening cycle and time can be determined to set.

10. Adjustments of UV radiation intensity and the light dosage are available.

11. Completing the UV hardening, the top shutter is automatically opened with a buzzer rung, and you can go to the next operation directly.

Detail

Detail