JECO split-type curing machine is suitable for the curing process for UV bonding of Housing assembly and IR filter in the manufacturing process of cellular phone camera module (VCM, VCA, MOBILE CAMERA MODULE).

JECO split-type curing machine is suitable for the curing process for UV bonding of Housing assembly and IR filter in the manufacturing process of cellular phone camera module (VCM, VCA, MOBILE CAMERA MODULE).

In addition, in the event of adding the pre-cure process at the lower part of the housing assembly to improve the product quality, it may obtain the effect of increasing extraction force amounting to maximum 15N compared with the existing IR attach process. There occurs no additional cost as the same curing machine and jig are used without any change in the layout.

UV bonding is also applicable to the SUB process [bonding of coil and FPCB (York area)], which can be done by the curing machine for IR attach purpose.

This UV in-line type UV curing machine is applicable in a variety of applications to SUB and MAIN process of the VCM process using the same equipment. Therefore, it may guarantee production speed and product quality with a minimum investment cost.

Even in case of any change in model that may occur later, it is not necessary to be modified in addition providing economic and efficient advantage.

It effectively supplemented the problems such as occurrence of foreign substance, temperature, etc. when being installed in the clean room based on a great number of delivery histories which can contribute to improvement of production yield rate. Therefore, the Machine is greatly competitive compared with the equipment supplied by the others.

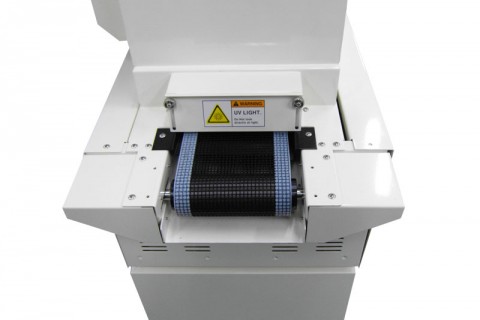

- In-line purpose rotary type UV curing machine.

- Height and rotation angle of two lamps can be changed, which enables to cure the product difficult to cure.

- Equipped with two lamps, which enables to increase curing speed.

- Mercury and metal halide lamps can be used simultaneously

- Small type curing machine that can be used in a small space.

- In-line structure which enables to immediate input to any line.

- Buzzer sounds when it reaches lamp replacement time.

- It enables UV curing for general electronic product as well as light product

- Simple manipulation

- It provides an excellent maintenance because UV lamp can be easily replaced.

- Height of upper lamp house is freely and simply controlled owing to its handle attached

- Height of upper lamp house can be adjusted with the lamp turned on

- Lamp height indicator is mounted being easy to refer to the height of lamp.

GENERAL SPECIFICATION

| ITEM | DESCRIPTION |

|---|---|

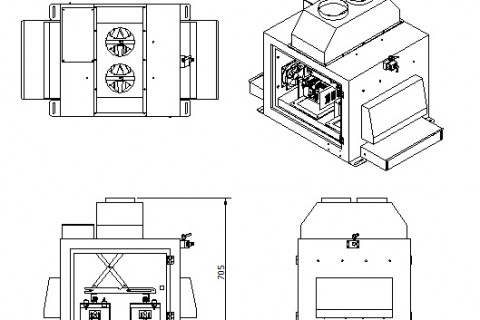

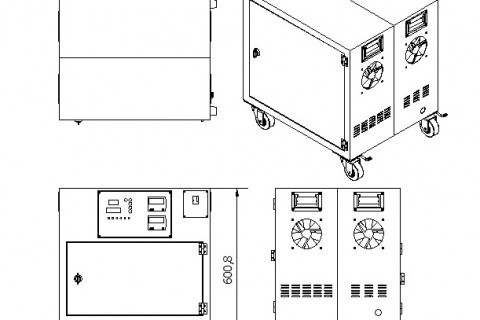

| SYSTEM DIMENSION | -Cure Machine : 960(W) *560(D)*705H) -Power Case : 560(W) *460(D)*600(H) |

| CURING WIDTH | 100(mm) |

| INPUT VOLTAGE | 220V, 단상, 50Hz or 60Hz |

| LAMP TYPE | Metal or Hg UV LAMP 1KW – 2EA |

| LAMP ARC LENGTH | 125 mm |

| TOTAL CONSUMTION | 1 KW / LAMP |

| WAVELENGTH | Metal : 320~420nm |

| IGNITION TIME | 3 MINUTE |

| REFLECTOR | COLD MIRROR |

| MAIN SWITCH | MAIN POWER ON/OFF SWITCH |

| LAMP POWER | LMAP POWER CONTROL ON/OFF SWITCH |

| LAMP HOUR METER | DISPLAY LAMP’S USED TIME(TOUCH PANEL) |

| LAMP AMPERE METER | DISPLAY LAMP’S CURRENT |

| TEMP METER | DISPLAY LAMP HOUSE TEMP |

| TIME RESET | HOUR METER RESET BUTTON |

| COLOR | STANDARD (IVORY) OR CUSTOM COLOR |

OPTION

| ITEM | DESCRIPTION |

|---|---|

| HOT MIRROR (152X52X2.2T) | 1~2EA (OPTION) |