This equipment is UV automatic in-line equipment aimed at applying the FPCB process conducted for UV bonding of window glass and touch panel in the cellular phone touch screen (OLED/AMOLED) manufacturing process to the automatic line. In case of existing equipment, it produces the product in such a manner that human worker input and discharge the product, and requires more labor cost compared with UV in-line curing method.

This equipment is UV automatic in-line equipment aimed at applying the FPCB process conducted for UV bonding of window glass and touch panel in the cellular phone touch screen (OLED/AMOLED) manufacturing process to the automatic line. In case of existing equipment, it produces the product in such a manner that human worker input and discharge the product, and requires more labor cost compared with UV in-line curing method. Meanwhile, productivity is extremely high compared with UV manual curing system as all the production process is fully automatic. There exists an initial investment cost burden. However, it is more economic compared with manual UV curing system if labor cost and increased productivity are considered. JHCI-5012TC is designed for only one worker to control all the equipment in the whole line from input to discharge stage aimed at minimization of the number of the workers that cope with the process line. It has also the convenience that all the system is automatically operated in compliance with UV automated in-line curing machine.

It also has an automatic lamp power controlling system that automatically compensates the drop of the amount of UV light according to the time lamp is used, which can monitor the real time production quantity.

In addition, it enables to monitor on real time basis by applying RMS communication and data tracking and cope with the manufacture of production within 6 inches.

- Complex UV curing machine is the curing machine that incorporates UV side and upper parts curing system.

- Electronic unit box in enclosed for the use of lower space of the equipment

- Both UV metal halide lamp and UV mercury lamp can be used.

- A sufficient amount of irradiation can be obtained through the illuminance in compliance with the product characteristic and free control of the speed of conveyor belt.

- It is designed to minimize temperature damage applied to the product through cold mirror/hot mirror and exhaust air flow balance.

- The machine’s lamp cooling is carried out in an air-cooling type – having a simple design structure and easy in maintenance. It maintains a stable UV lamp output through the adjustment of cooling quantity..

- With a coil ballast transformer in use, it supplies a stable voltage and current.

- With a simple control through touching function, it provides the worker with convenience.

GENERAL SPECIFICATION

| ITEM | DESCRIPTION |

|---|---|

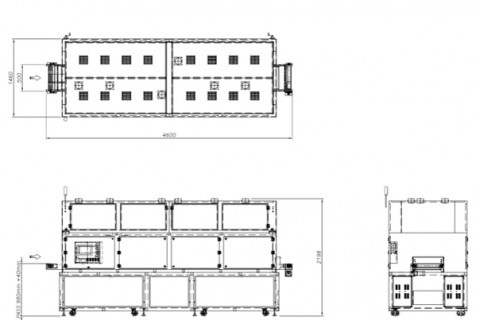

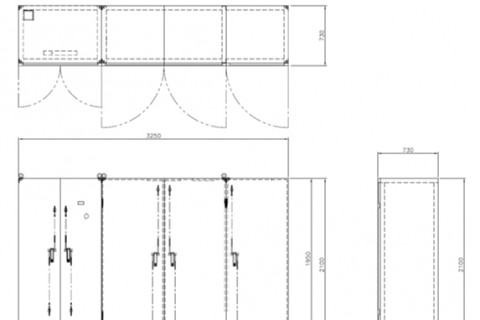

| SYSTEM DIMENSION | *4600 mm (L) x 1460 mm (W) x 2200 mm (H) *전장&트랜스박스 3250mm(W) x 730mm(D)x2100mm(H) |

| CURING WIDTH | FRONT 350mm SIDE 350mm |

| INPUT VOLTAGE | 220V , 3P, 60 Hz 300A |

| LAMP TYPE | METAL UV LAMP – 6~12EA |

| LAMP ARC LENGTH | 420 mm |

| TOTAL CONSUMTION | 3~5 KW / LAMP |

| WAVELENGTH | 200 ~ 420 nm(Peak : 365nm) |

| IGNITION TIME | 3 MINUTE |

| REFLECTOR TYPE | COLD MIRROR |

| HOT MIRROR (152X152X2.2T) | OPTION |

| MAIN SWITCH (NFB) | MAIN POWER ON/OFF SWITCH |

| LAMP AMPERE METER | DISPLAY LAMP’S CURRENT |

| LAMP TIME CHECK METER | DISPLAY LAMP’S USED TIME |

| LAMP ALRAM | ALRAM LAMP CHANGE |

| PLC & TOUCH SCREEN | OPTION |

| COLOR | STANDARD (IVORY) OR CUSTOM COLOR |