JECO Film-type Curing System that is designed for its curing zone to be separately installed has been developed to enable a direct application to the other equipment (System Equipment), which is designed so that it can be used effectively in (in line) optical film, glass printing curing, and production of UV silk printed matters. With a shutter mounted on it, the system enables to provide protection after UV irradiation. Therefore, it leads to the manufacture of film product in a stable quality (ROLL TO ROLL SYSTEM).

JECO Film-type Curing System that is designed for its curing zone to be separately installed has been developed to enable a direct application to the other equipment (System Equipment), which is designed so that it can be used effectively in (in line) optical film, glass printing curing, and production of UV silk printed matters. With a shutter mounted on it, the system enables to provide protection after UV irradiation. Therefore, it leads to the manufacture of film product in a stable quality (ROLL TO ROLL SYSTEM). In addition, it enables a high-speed production and facilitates a proper product management through its maintenance of high quantity of light and low temperature. It is easy to change lamp causing time loss to be minimized in replacing the lamp. With reference to the lamp module in applying this system that you have, you are required to consult with our technical department for its exterior size. Power supply is also at your option among electronic type or coil type, etc. UV lamp output can be adjusted by stages. Transformer is 3-step control, and the electronic type can be finely adjusted.

In case of applying the size, either small or large type is applicable. It is easy to upgrade the system including applying the UV sensor system.

1. JECO UV film curing machine has UV irradiation system at upper and lower areas. This is designed for film and glass printing purposes.

2. The machine can be equipped with metal halide lamp or mercury lamp.

3. Ballast is in an electronic type so that the output of lamp can be freely controlled.

4. This machine enables to secure a sufficient irradiation through an illuminance suitable for the product characteristic and the speed of roller freely controlled. It is designed to minimize temperature damage applied to the product through cold mirror/hot mirror and exhaust air flow balance.

6. The machine’s lamp cooling is carried out in an air-cooling type – having a simple design structure and easy in maintenance.

It maintains a stable lamp output through controlling the cooling capacity.

7. With a cylinder attached, UV curing zone is opened for maintenance purpose conveniently.

GENERAL SPECIFICATION

| ITEM | DESCRIPTION |

|---|---|

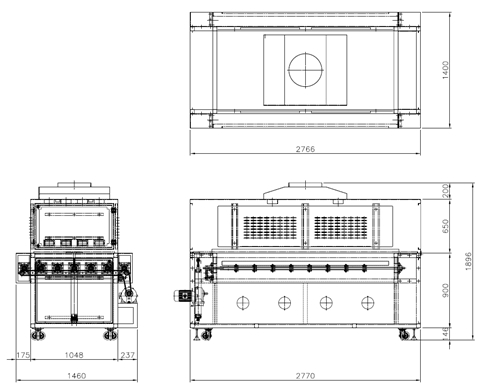

| SYSTEM DIMENSION | 1400 mm (L) x 2770 mm (W) x 1896 mm (H) |

| CURING WIDTH | SIDE 1600mm |

| INPUT VOLTAGE | 440V,380V, 220V 3P, 60 Hz |

| LAMP TYPE | HG , GA, METAL UV LAMP – 4EA |

| LAMP ARC LENGTH | 1900mm |

| TOTAL CONSUMTION | 20 KW / LAMP |

| WAVELENGTH | 200 ~ 420 nm(Peak : 365nm) |

| IGNITION TIME | 3 MINUTE |

| REFLECTOR TYPE | COLD MIRROR |

| MAIN SWITCH (NFB) | MAIN POWER ON/OFF SWITCH |

| LAMP AMPERE METER | DISPLAY LAMP’S CURRENT |

| LAMP TIME CHECK METER | DISPLAY LAMP’S USED TIME |

| LAMP ALRAM | ALRAM LAMP CHANGE |

GENERAL SPECIFICATION

| ITEM | OPTION |

|---|---|

| HOT MIRROR (152X152X2.2T) | OPTION |

| PLC & TOUCH SCREEN | OPTION |