UV Tape Remover is JECO wafer-purpose semi-automatic UV curing machine that can cure 8~12 inches. It is designed in the scan irradiation method where the lamp moves with the product fixed, which enables homogenous irradiation of the product by minimizing the tolerance of illuminance (using a filter) based on a long experience and technical competence. In addition, scan frequency can be pre-set, and therefore it is suitable for meeting the required amount of light depending on UV tapes that vary.

UV Tape Remover is JECO wafer-purpose semi-automatic UV curing machine that can cure 8~12 inches. It is designed in the scan irradiation method where the lamp moves with the product fixed, which enables homogenous irradiation of the product by minimizing the tolerance of illuminance (using a filter) based on a long experience and technical competence. In addition, scan frequency can be pre-set, and therefore it is suitable for meeting the required amount of light depending on UV tapes that vary.

Designed to purge nitrogen on the position of product (RING FRAME), it prevents inflow of oxygen. Therefore, the quality of product improves at the time of UV curing through preventing oxidization of UV surface. In addition, it enables high-speed production (option) and is easy to manage the product through the maintenance of low temperature (high amount of light).

Owing to the lamp height being available (manual, step control), it is easy to cope with change in the amount of light following the drop of lamp life. Easiness in replacement of lamp minimizes the loss of time for replacing lamp. In addition, it enables to adjust the UV lamp power output by steps (Transformer 3-step control)

- 1. Automatic equipment for 6~8 inch wafer UV curing.

- 2. With upper area shutter mounted, it enables to work without exposure to UV light.

- 3. With a safety sensor mounted on the shutter, it enables workers to work in a safe condition.

- 4. Upper shutter drive is operated with air cylinder.

- 5. There exists a space to place the product on when upper shutter is opened. UV curing efficiency can be improved through nitrogen purging.

- 6. Shutter is mounted between the product jig and lamp, and therefore the product is not exposed to UV during its setting process.

- 7. It has the quartz to place general type product on as well as the jig to place wafer product on.

- 8. UV curing is conducted with the movement of lamp with the product in a static condition; it causes less damage to the product.

- 9. It is possible to artificially adjust the times of curing, speed, output of lamp (3-step control), lamp height (3-step), etc., and therefore it is easy to set curing condition for any product and has the advantage of uniformity.

- 10. It is possible to adjust the intensity of UV irradiation as well as the amount of light.

- 11. When UV curing is over, upper shutter is automatically opened together with the sound of buzzer so that the next work can be continued immediatel.

- 12. It provides an excellent maintenance because UV lamp can be easily replaced.

- 13. Exhaust blower automatic damper is installed so as to prevent initial stage over-cooling phenomenon when the lamp is turned on.

- 14. Warming up function that raises the temperature at the curing area when curing the product sensitive to the temperature is added so as to build the temperature management system.

- 15. In order to over temperature of the curing area, the system of controlling the temperature through traveling (back and forth) of lamp is built.

GENERAL SPECIFICATION

| ITEM | DESCRIPTION |

|---|---|

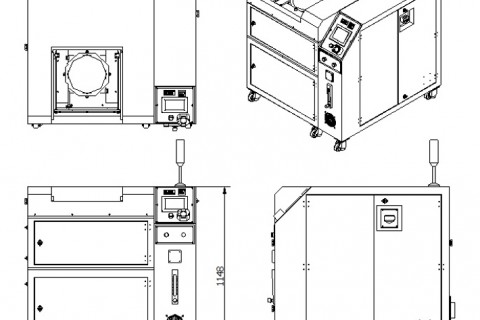

| SYSTEM DIMENSION | Cure Machine : 1080(W) *1125(D)* 1150(H) |

| CURING WIDTH | 8” |

| INPUT VOLTAGE | ORDER MADE |

| LAMP TYPE | Me or Hg UV LAMP – 1EA |

| LAMP ARC LENGTH | 375 mm |

| TOTAL CONSUMTION | 3 KW / LAMP |

| WAVELENGTH | 320 ~ 420 nm(Peak : 365nm) |

| IGNITION TIME | 3 MINUTE |

| REFLECTOR TYPE | COLD MIRROR |

| HOT MIRROR (152X152X2T) | (OPTION) |

| PLC CONTROL | MITSUBISHI : FX3U-48MR |

| PLC <-> TOUCH 통신 | MITSUBISHI : FX3U-232BD |

| PLC D/A CONTROL | MITSUBISHI : FX3U-4DA-ADP |

| TOUCH PANEL | AGP3301-L1-D24 |

| INVERTER CONTROL | LS산전 : SV004Ig5-2u |

| TOWER LAMP | ST45L-3-220-SZ |

| BUZZER | KSP-41S |

| UV SHUTTER (UV ZONE) | *AIR SILINDER 250mm *V GUID SYSTEM |

| TOP SHUTTER | *AIR SILINDER 450mm *LM RAIL SYSTEM |

| COLOR | STANDARD (IVORY) OR CUSTOM COLOR |

GENERAL SPECIFICATION

| ITEM | OPTION |

|---|---|

| UV SENSOR | UV 200 |

| SIGNAL | *CURE START/STOP *LAMP ON/OFF *RESET |

| HOT MIRROR | QUARTZ COATING |